Deep drawing – a precision process in sheet metal forming

Technical understanding and simulation for safe results

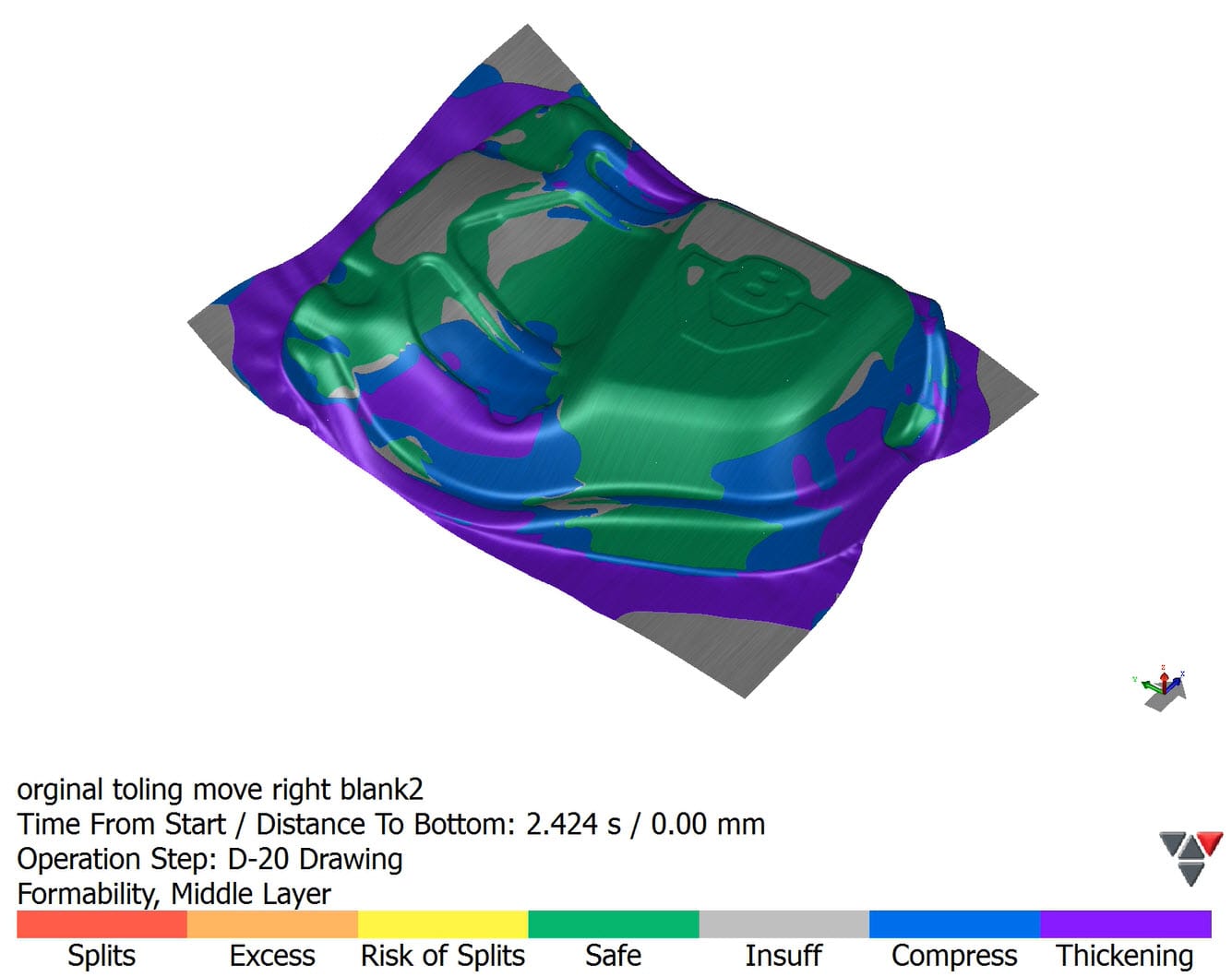

During deep drawing, the sheet is subjected to large forces that create internal stresses in the material. The strength of these stresses determines whether the material is deformed elastically, i.e. temporarily, or plastically, which means a permanent change in shape. When the stress exceeds the yield point of the material, the deformation changes from elastic to plastic. During the plastic deformation, a so-called deformation hardening effect occurs, which makes the material increasingly hard and thus requires higher forces to continue forming. At Sivab, we combine our practical experience with modern development methods. By using advanced simulations, we can analyze the sheet metal flow, predict springback and avoid cracking already at the planning stage. The tools are then manufactured with high precision and thoroughly tested in our own try-out press to ensure they work as intended.

Experience, quality and structure in each project

Working with deep drawing means dealing with small tolerances and large forces, which requires both an eye for detail and deep technical understanding. At Sivab, we have a long tradition of developing tools for complex sheet metal forming and our team of employees has the right skills in design, production and measurement technology. Together we have several hundred years of combined experience. We are certified according to ISO 9001 and 14001, which means that quality and environmental considerations are integrated into our way of working. Through our method ”The Sivab Way”, customers have access to a structured process where each step is based on analysis, verification and documented experience.

Prevention through analysis and verification

Our approach is based on solving problems before they arise. Already in the quotation phase, we conduct a feasibility review to assess the feasibility of an item. This allows us to identify risks such as cracks, creases or material stresses at an early stage and adjust the design before the tool is manufactured. This methodology means saving both time and money for our customers. By combining simulation, testing and accurate measurement, we achieve high process reliability. Our strength lies in the ability to create the right solution for each individual product.

A partner with knowledge, responsibility and a long-term approach

We have the knowledge, equipment and commitment to achieve precision at every stage, from planning to finished product. When you turn to us, you get a supplier who understands the process and the demands of production. If you want to develop new items or optimize existing tools – we are just a call away! Our business is based on the values of Knowledge, Will, Responsibility and Loyalty, which is a security for our customers. Our goal is to create long-term partnerships where every delivery exceeds expectations.